We work hand in hand with our clients to develop and evolve products over time

Research, develop and grow with us

High Performance and Ultra-High Efficiency Motors for Industrial Fans

Domel’s permanent magnet synchronous (PMS) motors are developed to offer and guarantee ultra-high performance at the IE5 efficiency level (and above), and a maintenance-free long lifetime.

Domel motor types NZA and ZZ are suitable to drive industrial fans.

Key features:

- 750W up to 55 kW (from 2 Nm to 180 Nm)

- speed up to 6,000 rpm

- efficiency level above IE5

- the motor is highly efficient over the whole operating range

- use of ferrite magnets

- top quality

- long lifetime

- very robust due to the high level of protection

With Ultra-High Efficiency to Reduce the Total Ownership Cost

Asynchronous motors are mostly used to drive industrial fans, especially at powers above 6 kW. The market is not so effectively covered by PMS and reluctance motors, as these require a higher initial investment. However, PMS motors have up to 40% less losses compared to the equivalent IE3 asynchronous motors due to the secondary magnetic field being generated from the permanent magnets rather than copper windings. At partial load the difference in efficiency is even higher.

Energy costs through the life cycle represent the majority of the overall operating costs. If operating costs can be reduced, profitability is increased. PMS motors guarantee high energy savings and hence reduced payback time due to much higher efficiencies compared to asynchronous motors. As an additional bonus, system also becomes more environmentally friendly.

Innovative motor construction

Domel has developed state-of-the-art motor construction, which offers the highest efficiency in small size and lightweight motors with the use of non-rare earth, ferrite magnets.

The unique electrical design enables us to offer motors with high operating speeds, up to 6,000 rpm. When increasing the speed of the motor, the difference in size and weight between asynchronous and PMS motors also increases significantly, in favour of the PMS motors.

To meet an application’s specific requirements for pressure, flow, volume, etc., variable frequency drives are often required. The majority of these drives are also capable of running PMS motors. There is thus no need to adjust the electrical part of system when using PMS motors.

More Domel insights:

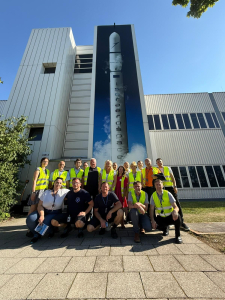

Last week, Domel took part in a professional excursion organized by the Slovenian-German Chamber of Commerce (AHK Slovenia), in cooperation with the Slovenian Space Office (Ministry of the Economy, Tourism and Sport), and under the patronage of the Bavarian Ministry of Economic Affairs, Regional Development and Energy.

Read article

As a globally established leader in motor component, research and development, and manufacturing, Domel is committed to delivering efficient, intelligent, and eco-friendly core power solutions for cleaning equipment. With innovative technology driving industry progress, our products are widely applied in both commercial and household cleaning machines, significantly enhancing overall performance.

Read article

At the regional innovation awards ceremony, our laboratory mill Millmix 30 received a gold award from the Chamber of Commerce - Gorenjska Regional Office, securing its place at the national level competition.

Read article

We are proud to have participated in the China–CEEC Expo 2025 in Ningbo, where Slovenia was featured as the guest of honor.

Read article

This year, Domel exhibited at the China Clean Expo (CCE) in Shanghai for the second time, marking a new step in our presence on the Chinese market. We thank our management for the trust and support, which enabled us to represent Domel with full autonomy.

Read article